The Nuotong team works together and actively prepares to ensure the safe, stable, and efficient operation of the gas supply system with excellent products and comprehensive services, fully meeting the strict requirements of semiconductor process equipment for high-precision gas. Continuously enhancing the competitiveness of enterprises provides solid technical support for the vigorous development of the semiconductor industry.

Design phase:

Customer demand analysis: Firstly, gain a deep understanding of the customer's specific needs for Gas boxes, including key parameters such as process types, flow control accuracy, response time, etc.

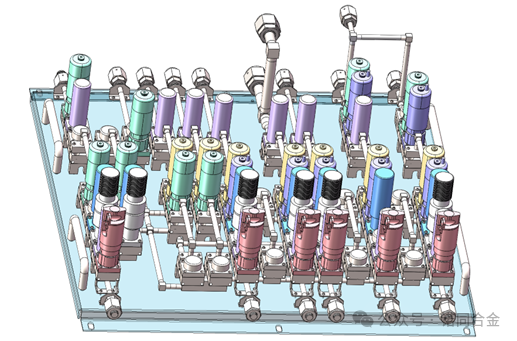

Optimization of gas path layout: Through reasonable gas path design, reduce the resistance and delay of gas flow, and ensure optimal design.

Component selection: High quality and high standard manual and pneumatic shut-off valves, pressure reducing valves, MFC, etc. are selected to ensure the stability and reliability of the air circuit.

Assembly stage:

Cleaning and preparation: Class 100 clean room, ensuring no impurities and pollutants.

Precision assembly: Customized installation fixtures to enhance sealing performance.

Quality inspection: A comprehensive quality control process ensures that each step meets the standards.

Testing phase:

Leakage detection: Use professional leakage detection equipment and methods to ensure no leakage phenomenon.

Functional testing: Test various functions of the Gas box, including switch speed, response time, flow control accuracy, etc.

Operation detection: Simulate the actual working environment to verify stability and reliability.